How to Use an Auger: A Guide from Autoguide Equipment

- frankleighonline

- Oct 1, 2024

- 3 min read

At Autoguide Equipment, we specialise in designing and manufacturing high-quality Auger Drivers in the UK, tailored for a range of applications. Whether you're using them for excavation, utility installations, or other projects, our Auger Drivers are versatile tools that can be attached to various types of equipment, including excavators, cranes, and even custom drilling rigs.

Understanding Auger Drivers

An auger is a spiral-shaped tool used for drilling holes into the ground, making it ideal for applications such as digging post holes, foundation work, and landscaping. Autoguide Equipment’s Auger Drivers are designed to handle various ground conditions and project requirements. Available in a range of sizes, these drivers are powerful, adaptable, and can be customised to meet your specific needs.

Steps on How to Use an Auger

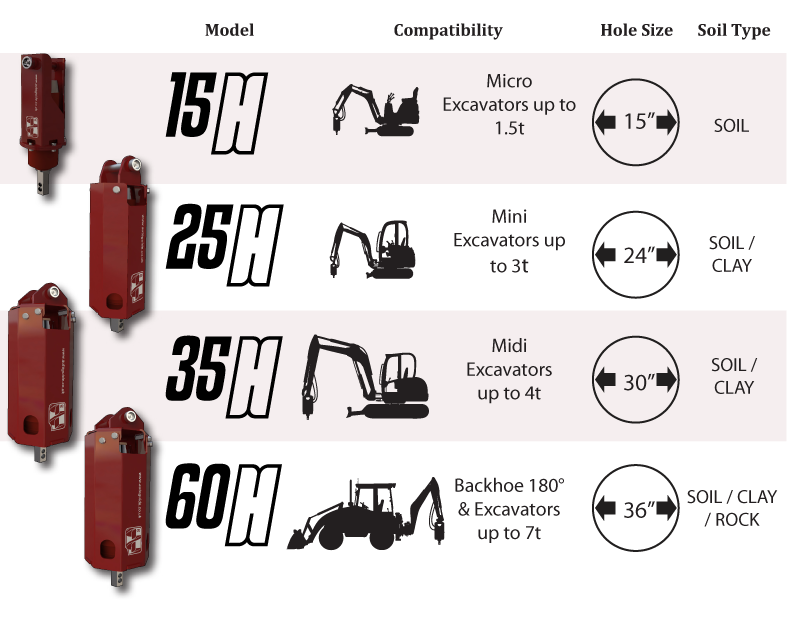

Choose the Right Auger Driver for Your Project Before starting, it's crucial to select the right size and type of Auger Driver. Autoguide Equipment offers a variety of models to suit different ground types and tasks. Whether you're working with a mini excavator for small-scale projects or a crane for larger jobs, we can supply a perfectly suited driver for your machinery.

Attach the Auger Driver Autoguide’s Auger Drivers are designed to be easily attached to various pieces of equipment. The attachment process will depend on the machine you're using—excavator, crane, or other. Always ensure that the auger is securely attached before beginning any work to guarantee safe and efficient operation.

Set the Torque Measurement One of the key features of our Auger Drivers is the ability to measure torque, if required. This is especially useful when precision is essential, such as when working in varying soil conditions. Our Auger Drivers can be equipped with torque measurement systems, ensuring that you achieve the right level of force needed for the job without risking over-torquing or damaging equipment.

Position and Begin Drilling Once the auger is securely attached, position it at the desired drilling point. Ensure that you operate the machinery at a steady pace to allow the auger to effectively penetrate the ground. If the ground is particularly hard, apply more torque as needed, but take care not to overload the machine.

Monitor Progress and Adjust as Necessary As the auger drills into the ground, keep an eye on the progress. If resistance increases or ground conditions change, adjust the speed or torque accordingly. Thanks to Autoguide’s precision engineering, our auger drivers allow for smooth adjustments, ensuring optimal performance even in challenging environments.

Remove and Clear the Auger Once you've reached the required depth, lift the auger from the hole. Ensure that any debris is cleared from the tool before moving on to the next hole. Autoguide’s robust construction ensures that our Auger Drivers can handle even heavy debris with ease.

Auger Drivers for All Applications

At Autoguide Equipment, we go beyond just providing auger drivers for standard machinery. We also manufacture custom drilling rigs, including all-terrain tracked and remotely controlled rigs. These are perfect for projects in difficult-to-reach locations or where precision is critical.

Why Choose Autoguide Equipment?

UK-Manufactured Quality: All of our Auger Drivers are designed and built in the UK, ensuring the highest quality and reliability.

Customisable Solutions: From standard models to specialised applications, our auger drivers can be tailored to meet your unique needs.

Advanced Features: With the ability to measure torque, our drivers provide precision and control on every job.

Diverse Equipment Compatibility: Whether you need an auger for an excavator, crane, or a custom drilling rig, we’ve got you covered.

If you're looking to invest in high-performance Auger Drivers, designed for reliability and precision, get in touch with Autoguide Equipment today. We're here to help you get the job done efficiently and effectively, no matter the project size or conditions.

Comments